Applications:

Tank, hopper or vessel weighing

The Rice Lake RL9000TWM Series stainless steel weigh module is ideal for use in tank, hopper, vessel and many other applications. The low-profile design offers an economical solutions in a competitive marketplace. This rugged, high-precision mount is designed for easy installation and does not require check rods or other stabilizing hardware. The stainless steel construction and welded seal offer additional protection in wash down areas.

This tank weighing system is designed for a tank with maximum weight (including whatever is inside) of 5,000 pounds. The system does not include a digital weight indicator (we recommend the Rice Lake 480+ which is linked below on this page) and it also does not include any installation or calibration. We recommend that you work with a local engineering company or local scale company in your area.

PART # ...... DESCRIPTION

98998 Mount kit, RL9000TWM 4ea 2500lb SST Includes RL9000TWM a JB4SS Jbox and 25ft of EL147HE

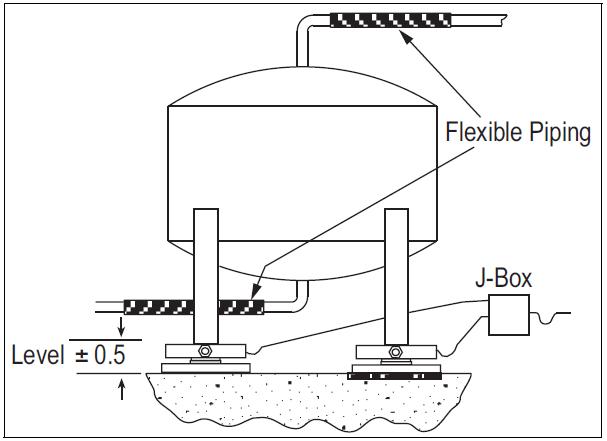

• Mounting surfaces for plates must be level. After installation, the top and bottom plates must be level within ±0.5°. If the mounting surfaces are not level, use shims and/or grout to level the mount.

• Check that the mount is level when the vessel is fully loaded, if possible, excessive deflections in legs and supporting structures can cause additional side forces which affect accuracy. Deflection of the mount top or base plate due to loading must not exceed ±0.5°. Reinforcement of legs or other support structures may be necessary to correct this. Vessels with long legs should have cross bracing applied between adjacent legs to keep them from spreading under load.

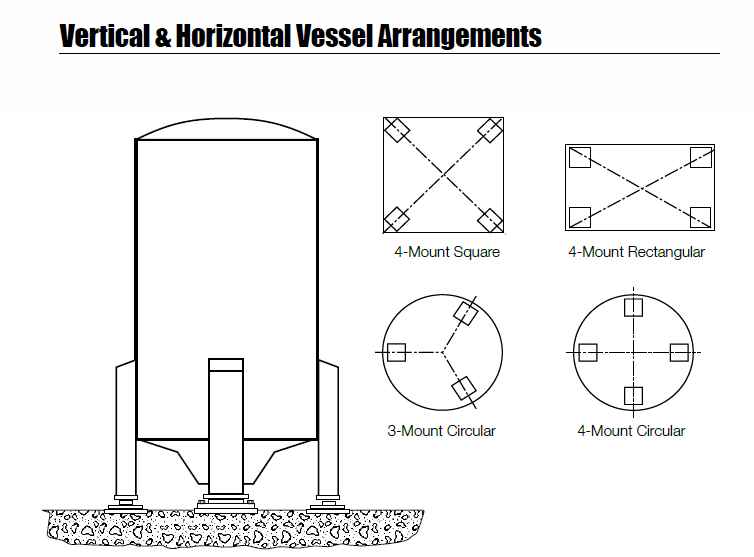

• Compression mounting systems use three, four, or more mounts. More than eight mount systems should be avoided as even weight distribution becomes extremely difficult to achieve. The load on each mount assembly should vary by no more than 20%. Add shims as needed, to achieve correct load distribution.

• Take extreme care to prevent overload damage. A tank or hopper can exert huge forces when dropped only a fraction of an inch.

• It is crucial that all piping or conduit be horizontal and flexible. If flexible piping is not used, make sure the distance from vessel to the first pipe support is 20-30 times pipe diameter. In smaller, lower capacity tanks and hoppers, isolating resultant forces becomes extremely critical.

• The weigh module assemblies should not be installed until all welding is completed. The heat generated from welding current passing through a load cell can damage the adhesive holding the strain gauge to the body. If possible, use a dummy mount when welding to maintain finished height. If welding is unavoidable after load cell installation, connect the ground in such a way that the current does not flow through the load cell. Protect the load cell and cable from weld splatter. Example: if welding on the mount top plate, the ground must be connected to the vessel, not to the mount base or support structure.

• We encourage you to find a local company in your area and work with them to professionally install and calibrate the tank weighing system. We only provide the equipment, we are not able to provide any installation services.