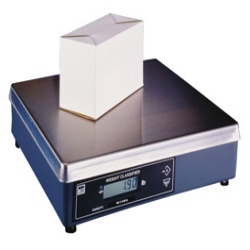

You probably have noticed over the past decade how much more emphasis has been placed on box dimensions (or pallet dimensions) when shipping your items. Back in the day, you just placed your box onto the Mettler Toledo BC60 shipping scale (actually back then it would have been the PS-60 scale) and the weight populated into UPS Worldship software on your computer and you printed your box label. It was simple and easy.

Fast forward a few years and now there is an additional step involved. You need to enter the box dimensions into UPS Worldship (or whatever shipping software you use). Now, this process can take anywhere from a few seconds to a few minutes depending on how big the box is and if you have a tape measure handy. Other factors might include how motivated your shipping employee is to actually manually measure the box and if they can manage to measure and enter the three numbers correctly.

This has become a very important part of shipping…. especially if you’re shipping fairly decent size boxes that don’t weigh a whole lot. In that case, the dim weight is going to be utilized and if you didn’t enter the dimensions, you will have to pay more than what is listed on the computer screen more than likely.

Cheap Ways to Measure Boxes for UPS / Fed Ex Shipping Dimensions

So what are some ways to speed up the shipping process? Well, if you ship A LOT of boxes each day, then you might be a great candidate for a dimensional weight scale. These can speed up the process automatically and accurately. The downside with this solution is it can be costly. However, there are several free or low cost ways to handle box dimension measuring for UPS.

Two or three tricks that we do.

- In UPS Worldship there is a package type editor which allows you to enter popular packages that you ship often. So, we typically store a lot of our popular box sizes in there. Measure the box once and enter it into the Package Type Editor. Then when you ship this box out in the future, you choose it from a drop down menu. This makes the shipping process go fairly smooth.

- If we don’t have the package stored in our package editor, you can also usually find the box dimensions printed on the bottom of the box. You often see this with uline boxes for example. So, what you can normally do is add one to each amount and that should cover your dimensional measurement. So for example, the box is a 10x6x4. We would typically enter it as 11 x 7 x 5. We can do this quickly and fairly accurately as well. Bonus Tip: If you’re re-using a box, sometimes the dimensions will be on the old shipping label.

- The other thing we do is: keep a yard stick near the shipping area. And KEEP IT THERE. You can actually measure a box pretty quickly if you have the measuring tools right beside you and the computer.

We hope this helps you out. I’m sure most of you probably already do several of the things that we’re doing. Most companies would have to ship quite a few boxes out everyday to justify the cost of a dimensional weight scale and measuring system. But, with a little bit of effort, you can ship your boxes pretty accurately using a version of what we mentioned in the article.