In today’s fast-paced world, efficient and accurate handling of small parts is crucial for businesses to thrive. The key to achieving this lies in the use of accurate counting scales, specifically a counting scale for small parts.

These indispensable tools not only save time, but also reduce errors, cutting down on waste and improving customer satisfaction. In this blog post, we’ll explore the best counting scale choices, how they work, factors to consider when selecting the right parts counting scale, and their applications in various industries. Let’s unlock the efficiency your business needs this year and beyond.

Short Summary

-

Precision counting scales are essential for businesses dealing with small parts, providing features such as highly accurate average piece weight determination, easy to read LCD displays and full numeric keypads.

-

Select the right digital counting scale by considering factors like capacity & accuracy requirements, lightest piece weight part, highest total gross weight & budget.

-

Maximize accuracy through proper setup/calibration and sample size selection. Consider environmental factors to ensure reliable results.

Understanding Counting Scales that work best for Small Parts

Counting scales are essential tools for verifying high volumes of identical parts and can perform division and multiplication functions in addition to weighing. They come with a range of features such as LCD displays, full numeric keypads, and stainless steel or ABS plastic construction, ensuring durability and ease of use.

But how do these scales work, and what makes them indispensable for businesses dealing with small parts? Let’s delve into the key components and features, as well as the mechanism behind their remarkable accuracy.

Key Components & Features

The heart of a counting scale lies in its essential components and features. An LCD display serves as the window into the scale’s functions, presenting vital information such as piece count, average piece weight, and net weight. The numeric keypad and softkeys facilitate data entry and menu navigation, while database management capabilities and optional interfaces enable seamless integration with your business’s existing systems.

Some models even boast advanced features like color changing display technology, which uses color-coded indicators to show if a product meets its tolerance specifications. All these features come together to provide a seamless, user-friendly experience, maximizing the efficiency of your counting inventory processes.

How The Scales Work

The magic of counting scales lies in their ability to measure the weight of a sample of parts and multiply that weight by the number of parts in the sample, determining the total weight of the entire batch. To achieve this, the scale’s internal resolution must not exceed the weight of one part, and the sample scale capacity should not exceed 10,000 times the piece weight.

This careful balance of capacity and resolution ensures that counting scales can handle a wide range of small parts with incredible accuracy, making them an indispensable tool for businesses dealing with high volumes of identical parts.

Selecting the Right Parts Counting Scale

Choosing the perfect counting scale for your warehouse or business is not a decision to be taken lightly. It involves considering factors such as capacity and accuracy requirements, the lightest piece weight part, and the highest total gross weight that the scale must weigh. Additionally, the scale’s ruggedness, reliability, and high internal resolution are crucial factors. Budget considerations also play a vital role, as the cost of maintenance and any additional features should be taken into account.

So, how do you navigate this complex landscape and select the right counting scale for your specific needs? You can look at a buyers guide or continue reading and let’s break down the selection process into key factors: capacity and resolution, features and functions, and budget considerations.

Capacity and Resolution

When it comes to capacity and resolution, it’s essential to select a counting scale that’s appropriate for the size of the parts you’re counting. The internal resolution should be less than one part, while the sample size should be no larger than 10,000 times the piece weight. This ensures that the scale can accurately count the parts with no errors, regardless of the size of the parts.

Additionally, consider the scale’s maximum capacity and whether it offers rechargeable batteries or a power cord for added convenience and flexibility.

Features and Functions

The features and functions of a counting scale can make all the difference when it comes to efficiency and ease of use. Look for advanced features such as color changing display technology, which uses color-coded indicators to show if a product meets its tolerance specifications, and an alphanumeric keypad for easy entry of part numbers and other data.

Database storage capabilities can also prove invaluable for monitoring inventory and other information. By selecting a scale with the right combination of features and functions, you can ensure that your counting processes are as smooth and efficient as possible.

Budget Considerations

Budget considerations are an important aspect of selecting the right counting scale. While it’s crucial to invest in a durable, reliable scale with a high internal resolution and a counting feature, it’s also important to stay within your budget. Consider factors such as the cost of maintenance and any additional features, as well as rental options if your business only conducts periodic inventory counts.

By weighing these budget considerations, you can find the perfect counting scale that meets your needs without breaking the bank.

Maximizing Accuracy with Counting Scales

To truly unlock the potential of counting scales, it’s essential to maximize their accuracy. This requires proper setup and calibration, careful sample size selection, and consideration of environmental factors. By paying close attention to these aspects, you can ensure that your counting processes are as accurate and efficient as possible, allowing you to reap the full benefits of your investment in a counting scale.

Let’s explore each of these factors in more detail.

Proper Setup and Calibration

Setting up and calibrating your counting scale correctly is crucial for achieving the highest level of accuracy. This includes positioning the scale away from air conditioning vents and drafts, using electrical outlets that are distanced from machinery or fluorescent lights, and dissipating any static charges from forklifts.

It’s also important to take a minimum of 10 samples, leverage the piece-weight enhancement feature to optimize samples, and confirm that tare containers are correctly marked. By following these setup and calibration procedures, you can ensure that your counting scale is primed to deliver the most accurate results possible.

Sample Size Selection

Choosing the right sample size is critical for maximizing accuracy with counting scales. As a general rule, sampling 100 pieces will give you the best results. This ensures that your scale can accurately count the parts with minimal errors, regardless of the size of the parts being counted.

By carefully selecting the appropriate sample size, you can ensure that your counting scale is able to deliver the most accurate and reliable results possible.

Environmental Factors

Environmental factors such as temperature, humidity, and air pressure can have a significant impact on the accuracy of your counting scale. To minimize these effects, it’s essential to choose a scale designed to be resistant to environmental factors, such as a stainless steel scale.

Additionally, the scale should be placed in an area that does not experience extreme temperatures, humidity, or air pressure. By taking these factors into account, you can ensure that your counting scale is able to deliver the most accurate and reliable results, regardless of the environment in which it’s used.

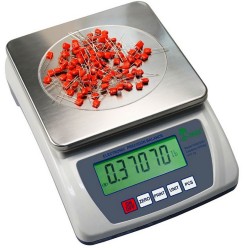

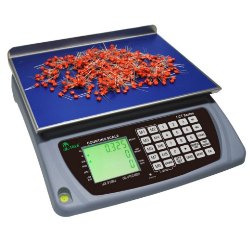

Popular Counting Scale Models for Small Parts

Now that we’ve explored the ins and outs of counting scales, let’s take a closer look at some popular models designed specifically for small parts. These high-quality counting scales offer a range of features and capabilities to suit the unique needs of businesses dealing with small parts.

In this section, we’ll introduce you to the Avery Weigh-Tronix ZK830, the Ohaus Ranger Count 4000, and the Pennsylvania 7600 Counting Scale, and discuss their key features and advantages.

Avery Weigh-Tronix ZK830

The Avery Weigh-Tronix ZK830 is a compact and portable counting scale that boasts a large LCD display, numeric keypad, hi/lo check function, and RS232 serial interface. With fast and reliable counting capabilities, a high-resolution digital Quartzell base, and configurable modular system, the ZK830 offers an unrivaled sampling accuracy.

Its innovative functional features and outstanding overload protection make it a top choice for businesses in need of a high-quality counting scale.

Ohaus Ranger Count 4000

The Ohaus Ranger Count 4000 is a rugged counting scale designed for industrial use. It features a large, clear LCD display and a sturdy stainless steel platform, making it perfect for a variety of applications. With weighing, parts counting, check counting, and accumulation capabilities, as well as seven application modes, the Ranger Count 4000 offers a high-resolution display and internal counting resolution for precise counting and weighing performance. Its IP54 protection and removable terminal make it a durable and versatile choice for any business.

Pennsylvania 7600 Counting Scale

The Pennsylvania 7600 industrial counting scale is a premium model designed for industrial and commercial use. Featuring Strain Gauge Weighing Technology, this versatile scale is available in a variety of weight capacities. Its full keypad, system-friendly design, and powerful RS-232 make it easy to integrate into your existing operations, while its rugged cast construction ensures durability.

With a 4-year limited warranty and a straightforward counting feature, the Pennsylvania 7600 is an excellent choice for businesses in need of a reliable parts counting scale. Optional battery power for portable use.

Applications of Counting Scales in Various Industries

Counting scales have a wide range of applications across various industries, from automotive parts and electronics to plastic or metal manufacturing and distribution. They’re also utilized in the mining industry for sustained and extended use.

In this section, we’ll explore the specific applications of counting scales in manufacturing, warehousing and distribution, and quality control, shedding light on how these versatile tools can revolutionize the way businesses handle small parts.

Manufacturing

In manufacturing, counting scales are essential for verifying the correct number of parts and preventing material waste and loss of customers. They’re also invaluable for cycle counting, a method of verifying inventory accuracy through the process of counting a limited portion of inventory on a recurring basis.

This ensures that the correct number of parts are used in the production process and that the parts have the correct weight, resulting in reduced waste and improved customer satisfaction. Accurate counting of goods also contributes to efficient assembly line scheduling, minimizing delays and enhancing overall efficiency.

Warehousing and Distribution

In warehousing and distribution, counting scales play a crucial role in ensuring that the exact number of items are shipped and received, and that the items are of the correct weight. By verifying the count accuracy of received goods, businesses can prevent shipping errors and locate missing parts, reducing the risk of costly mistakes and unhappy customers.

Counting scales also help to streamline inventory management, improving the overall efficiency of warehousing and distribution operations.

Quality Control

In quality control, counting scales are indispensable for fast cycle counting and package-count checks. By precisely counting and weighing items for inspection, businesses can ensure that the appropriate quantity of items are inspected and that the items are of the appropriate weight. This not only ensures customer satisfaction, but also optimizes profits by preventing the loss of valuable goods.

Counting scales truly shine in quality control applications, contributing to the overall success of businesses across various industries.

Maintenance and Troubleshooting

To get the most out of your counting scale, it’s important to properly maintain and troubleshoot the device. This involves regular scale maintenance and addressing common counting issues with the appropriate solutions. By staying on top of maintenance and troubleshooting, you can ensure that your counting scale continues to perform at its best, delivering accurate results and maximizing efficiency in your business operations.

Let’s take a closer look at the maintenance and troubleshooting procedures for counting scales.

Regular Scale Maintenance

Proper maintenance of your counting scale is essential for ensuring its accuracy and longevity. This includes cleaning the scale with a soft cloth and mild detergent, checking its calibration regularly, and replacing any worn parts.

It’s also important to keep the scale’s foundation free of debris by sweeping and vacuuming the area and ensuring the scale is properly grounded. Finally, scheduling a professional inspection at least once a year can help to identify and address any potential issues, keeping your scale in top working condition.

Common Counting Issues and Solutions

Addressing common counting issues is crucial for maintaining the accuracy and efficiency of your counting scale. Some of the most common issues include human error, piece weight deviation, and environmental factors such as temperature, humidity, and air pressure. To address these issues, it’s important to follow proper setup and calibration procedures, select an appropriate sample size, and take environmental factors into consideration.

By proactively addressing these common counting issues, you can ensure that your counting scale continues to deliver accurate and reliable results, boosting the efficiency of your business operations.

Summary

In conclusion, accurate counting scales for small parts are essential tools for businesses in various industries, helping to improve efficiency, reduce waste, and enhance customer satisfaction. By understanding how counting scales work, selecting the right model for your needs, and properly maintaining and troubleshooting the device, you can unlock the full potential of these versatile tools. With the right counting scale in your arsenal, you’ll be well-equipped to tackle the challenges of managing small parts, driving your business to new heights of success in 2023 and beyond.

Frequently Asked Questions

What scale do you use to measure small things?

When measuring small things, the most common scale to use is a gram scale, also known as a laboratory balance. This scale uses metric measurements to accurately weigh even tiny amounts of materials. Many of these balances have a counting function.

How do you count small items by weight?

To count small items by weight, one must first take a sample of the parts and place them on the scale platform. Enter the number of parts in the sample, then calculate the average piece weight using the scale.

Once the piece weight is known, place the entire batch of parts on the scale to get an accurate count.

What is a counter scale?

A counter scale is a versatile and accurate weighing instrument that allows for the measurement of both weight and item quantity. It can be used for checkweighing and parts counting tasks, enabling users to quickly and reliably count or weigh objects simultaneously.

This instrument is ideal for a variety of applications, such as inventory control, quality assurance, and production control. It is also useful for weighing items that are difficult to count, such as small parts.

How to use a counting scale?

To use a counting scale effectively, just place a known quantity (say 10 pieces) of the same items on the scale. On many scales, that would mean entering 10 and then pressing the sample key. Then simply weigh the entire sample to get the number of pieces. This straightforward process allows you to accurately count out pieces quickly and efficiently.